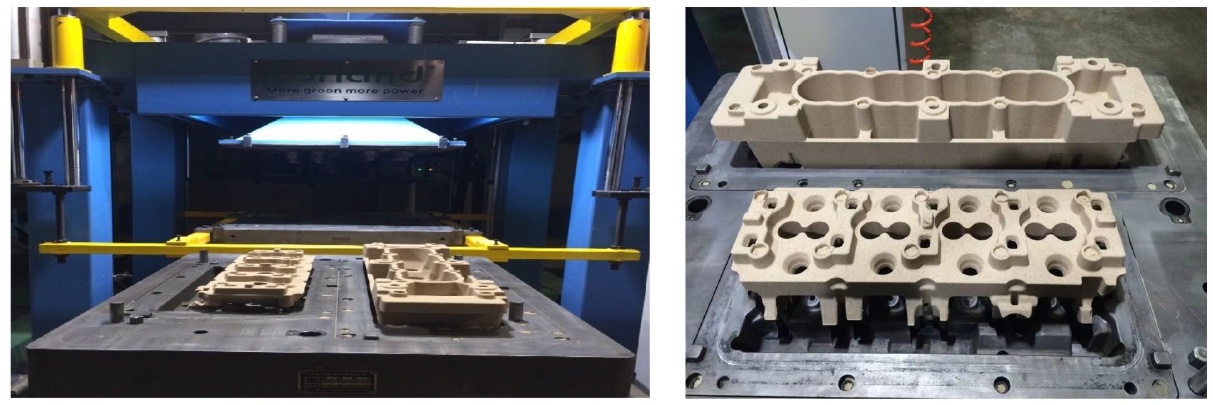

For customers, the application of cold core machine has the characteristics of high production efficiency and different casting time, which is more suitable for the production of the core of the traditional internal combustion engine cylinder head and the core of the subframe of some new energy vehicles.

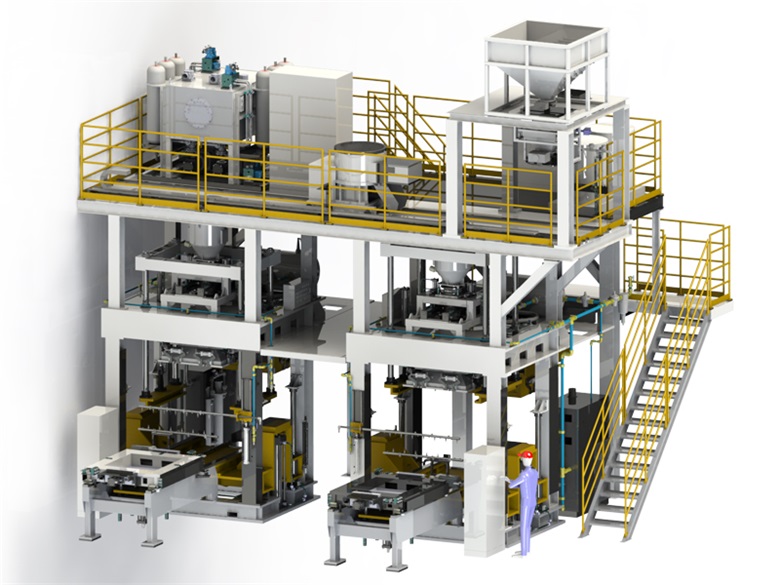

The trolley moves to the mold closing station, the mold is solidified by sand shooting, and the core is obtained. When the mold is opened, the core is actively pushed up to leave the sand core in the sand box, and the trolley takes it to the fetching station. In order to solve the serious odor of the cold core machine blowing, improve the integrity of the equipment, and facilitate the operator to participate in the core making operation more conveniently, different from the traditional single cold core machine, we add the enclosure screen and related configuration.